Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

Segmental Adhesive Challenges High Temperature of 50 ℃ on Concrete Tower Assembly

When the scorching sun roars the construction site of the wind turbine hybrid tower, an air temperature of 40 ℃ is already the norm, and the concrete base surface soars above 50 ℃ under direct sunlight - such high temperatures are undoubtedly an "ultimate test" for prefabricated segment splicing adhesive. The difficulties of colloidal flow hanging, uncontrolled solidification, and reduced durability during high-temperature construction not only slow down the progress of the project, but also pose hidden safety hazards. Today we are launching a prefabricated segment splicing adhesive specially developed for extreme high temperature environments, bringing a new solution for mixed tower construction.

Three major pain points of high-temperature construction: the "curse" of mixed tower assembly

The challenge of high temperature on the construction of mixed tower splicing is far more complex than imagined. The combined effects of environmental temperature, substrate temperature, and material temperature frequently cause the failure of conventional splicing adhesives, with the main pain points concentrated in three aspects:

① Colloidal flow and bonding failure

High temperature will sharply reduce the viscosity of colloids, making it easy to flow along the tower wall during construction. This not only causes a large amount of material waste, but also leads to insufficient filling of the joint glue, directly affecting the compactness of the tower joint and burying structural safety hazards.

② Uncontrolled solidification and construction risks: High temperatures can accelerate the solidification of colloids, greatly reducing the operable time, resulting in incomplete assembly before solidification, or insufficient strength due to insufficient solidification, seriously threatening the construction quality.

③ The continuous deterioration of durability in high-temperature environments will accelerate the aging of colloids, significantly reducing their resistance to moisture and fatigue. Over the long term, the strength of the colloid will weaken, directly affecting the design life of the wind power hybrid tower and posing a high cost risk for later operation and maintenance.

High temperature splicing adhesive: six core advantages to solve high temperature problems

High strength and high adhesion

In the high temperature range of 35 ℃ -50 ℃, the colloid still maintains high strength and high adhesion performance, stably transfers loads, and ensures the long-term stability of the splicing structure.

High thixotropy without sagging

High thixotropy index, no dripping during scraping and coating, suitable for both horizontal and vertical seam construction. 20mm thick adhesive can be placed at high temperature for 50 minutes without dripping, reducing material waste.

Ultra long operable time

In high temperature environments, the colloid can be operated for at least 30 minutes to avoid rapid solidification of the colloid that may affect the normal progress of construction. The adhesive assembly time is sufficient to adapt to high temperature conditions.

Long term non yellowing

Solving problems from raw materials, long-term use without yellowing, and longer lifespan.

Durable and corrosion-resistant

Effectively preventing water and medium erosion, durable and fatigue resistant, can maintain stable performance in long-term high temperature and high humidity environments, providing reliable guarantee for the design life of the mixing tower.

Compact and easy to apply

Apply the gel tightly and easily stirred, apply evenly, and avoid local stress concentration that may cause cracking.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

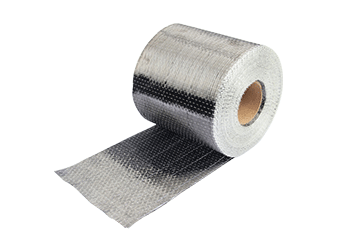

High strength, unidirectional carbon fiber wrap pre-saturated to form a carbon fiber reinforced polymer (CFRP) wrap used to strengthen structural concrete elements.

HM-120SC Segmental Bridge Adhesive is a solvent free, two-component, high modulus, moisture-insensitive epoxy adhesive specifically developed for use as an adhesive for precast segmental bridge elements.

Element bonding adhesives provide a rigid bond between elements to transfer load