Strengthening RC Columns

Steel Jacketing Techniques

Select language

Steel Jacketing Techniques

When the column has three problems:

The building is located in a dry environment, and the carbonization depth of the concrete surface exceeds the thickness of the protective layer, resulting in corrosion of the longitudinal reinforcement and stirrups, and a reduction in the cross-section of the steel bars. At the same time, the expansion of the corrosion products will aggravate the cracking of the concrete, forming a "vicious cycle."

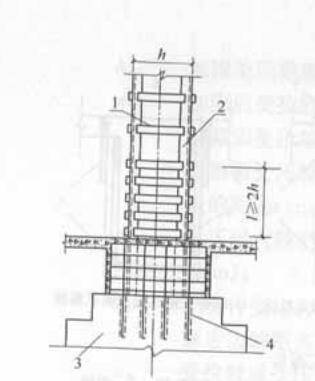

When the column has three problems: "bearing capacity does not meet the requirements, poor stability, and deteriorated durability", and there are strict requirements for increasing the cross-sectional size, steel jacketing reinforcement is one of the best choices.

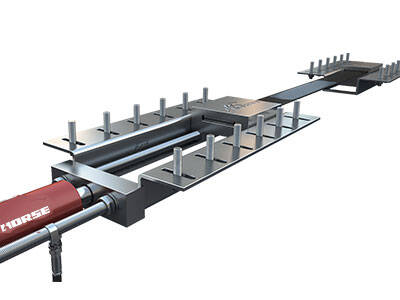

Steel jacketing:

Significantly improves load-bearing capacity and offers a wide range of options.

The core value of steel jacketing is to effectively compensate for the mechanical deficiencies of the original column. By synergizing steel sections (usually angle steel and steel plates) with the original concrete column, it significantly improves various load-bearing capacities.

Repairing deteriorated structures: For columns with concrete spalling and steel corrosion, steel jacketing can first fill cracks and repair damaged areas with interface adhesive. Then, the concrete is constrained by steel sections and structural adhesive is injected to prevent further deterioration and extend the service life of the column by 20-30 years.

Website Map | Corporate | Contact | Privacy